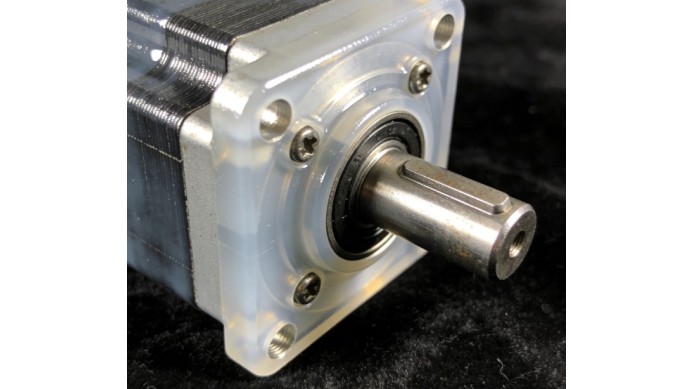

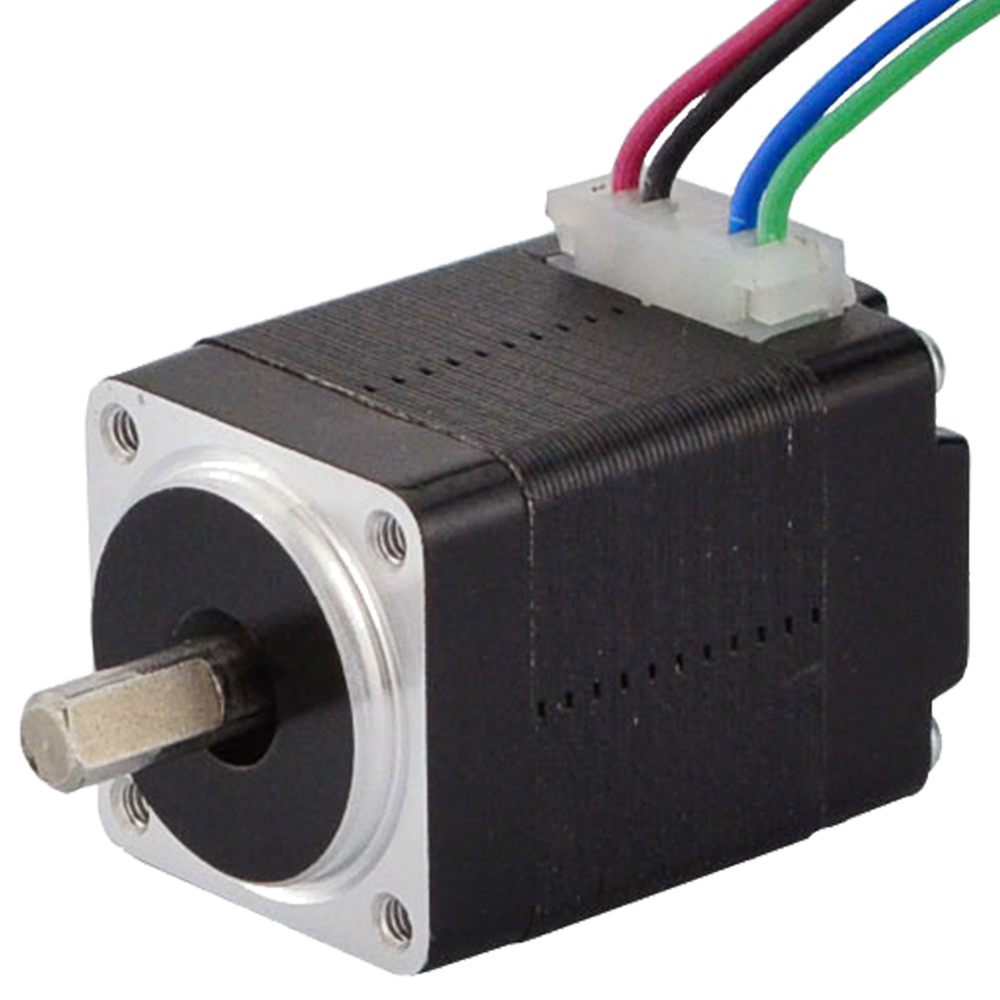

TThe conventional approach to addressing corrosion has been to encapsulate the stepper motor in an attempt to block moisture ingress. While shaft seals and housing gaskets can slow moisture penetration, they cannot completely prevent it. Over time, aided by temperature fluctuations, moisture inevitably finds its way past these seals. Once inside the motor, the same seals then trap the moisture, hindering its escape. Additionally, shaft seals introduce rubbing friction, which typically reduces motor torque by 4 % to 20 %. Furthermore, as the motor undergoes repeated thermal cycling—heating during operation and cooling afterward—the air inside expands and contracts. During contraction, small amounts of moist air are drawn into the motor interior. Over time, this accumulated moisture leads to internal corrosion, a vulnerability particularly pronounced in hybrid stepper motors due to their fine internal components and magnetic materials.

A New Design Technique For Stepper Motor Prevent Corrosion

Currently, a new design technique produces corrosion-proof and waterproof stepper motors, extending the stepper motor life in harsh rugged environment. Stepper motors used at outdoors condition are susceptible to temperature extremes and moisture, causing internal corrosion that quickly shortens stepper motor life, and causing early stepper motor failure also. However, the new technique to preventing corrosion and early failure uses a system of rugged corrosion proof coatings that are applied to all metallic surfaces both inside and outside the stepper motor, protecting them from moisture and corrosion.

Previously used coatings lacked the durability needed to adequately protect the soft‑iron magnetic components and other metallic materials inside a stepper motor throughout its intended service life. The new approach involves applying a specialized, ruggedized coating to every exposed surface and internal structure—including the rotor, stator, windings, laminations, and housing—effectively encapsulating all ferrous and aluminum parts susceptible to corrosion. Material selection and coating formulations are specifically tailored to each component: permanent magnets receive treatments that preserve magnetic strength, aluminum housings are coated for environmental resistance, and steel laminations are protected without compromising electrical or magnetic performance. This comprehensive, component‑specific protection ensures long‑term corrosion resistance while maintaining the motor’s mechanical integrity and operational efficiency.